· Benjamin Božič · 3 min read

The story behind the Flowerpad: From a Farewell Gift to a finished product

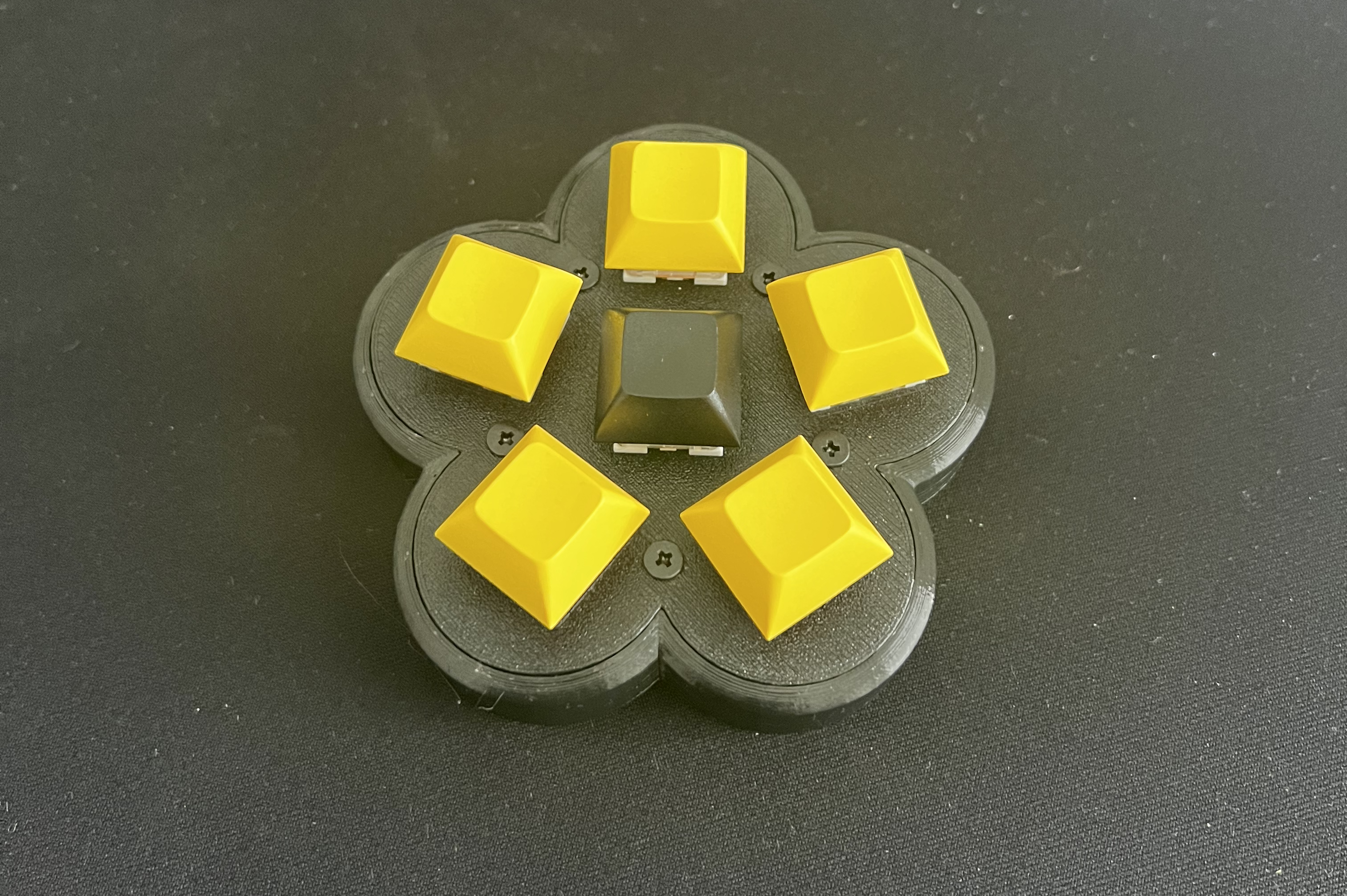

Delve into the origins and development process behind the Flowerpad

Innovation often springs from the most heartfelt desires. In the case of the Flowerpad, the genesis was not a business initiative, but the simple intention to create a thoughtful, unique, and functional farewell gift for two colleagues.

Having previously dabbled in 3D printing and hand-wiring of macropads and split keyboards, the idea of creating another standard rectangular macropad seemed prosaic. Inspired by the recipients’ love for flowers, the idea of a flower-shaped pad began to germinate. However, translating this concept into reality proved to be a challenge, given my limited knowledge in 3D modelling.

The project encountered an unexpected hiatus after a personal relationship ended, stalling the initial 3D design process. I was back to square one until my brother stepped in, breathing life into the sketches I had made and creating an executiable 3D model.

Several rounds of refinements later, I had a design I was content with. Assisting its functionality was a customized QMK firmware, replete with six operational layers aimed at general usage, excel, word, multimedia, a ‘troll’ layer echoing our common phrases, and a layer switching function.

Post gifting, due to the time-intensive process, the project was put on hold. It was not until a year later when I left full-time employment to focus on my own enterprise that I could revisit the Flowerpad. This time around, I got the opportunity to learn 3D modelling basics using a Shaper3D license, allowing me to quickly finalize the case design.

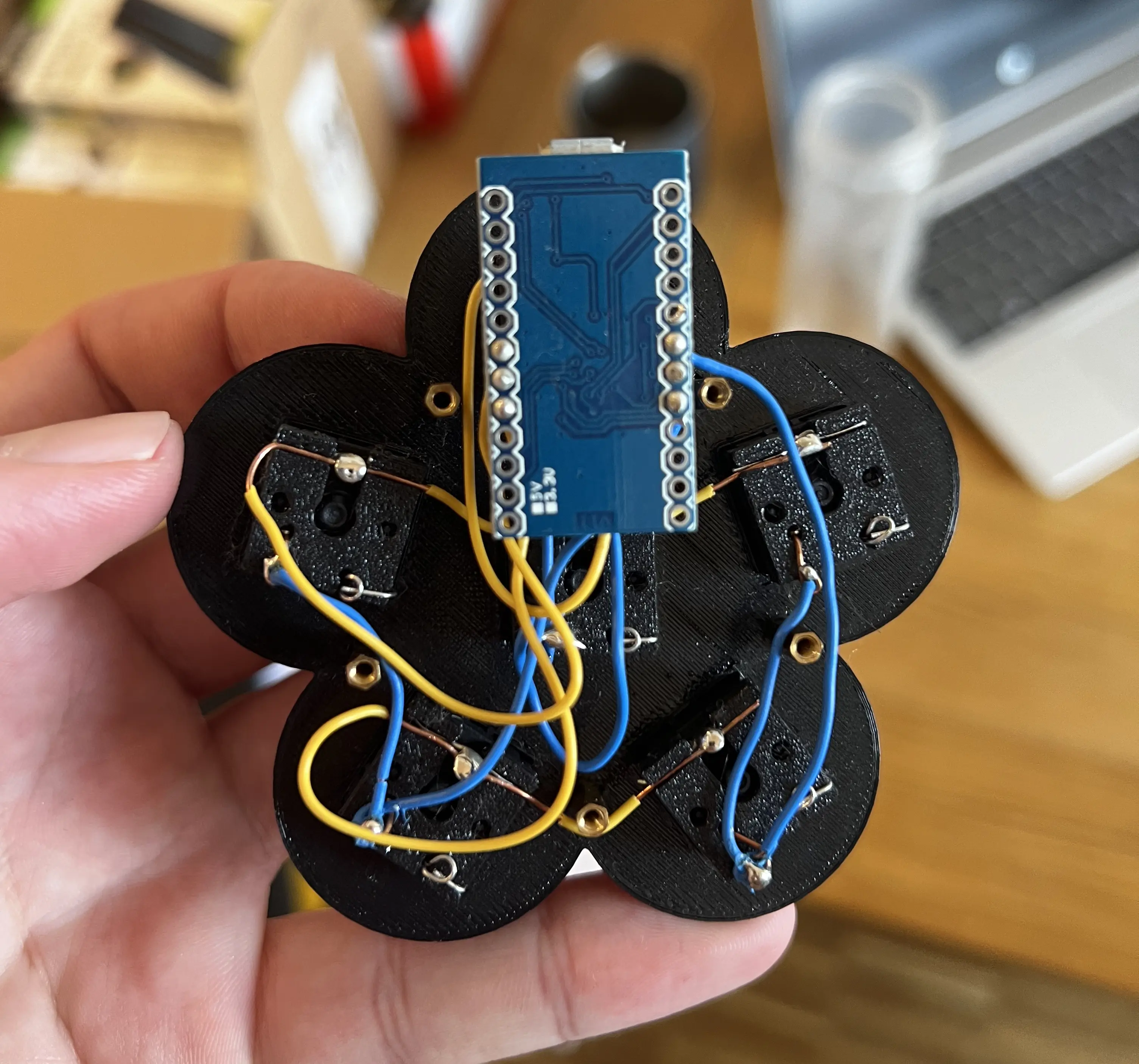

Further immersing myself in the mechanical intricacies, I learnt KiCad to create a custom PCB. The process entailed overcoming space constraints, that required a 90 degrees rotation of the hotswap socket and offsetting the microcontroller by 0.5mm. Despite initial PCB prototypes being larger than planned, with diligent redesigning efforts, I managed to create a much sleeker version.

The final significant change was switching the Pro micro for a more efficient rp2040 based controller. The firmware needed some tweaking too, but with the kind help and feedback of the QMK team, I successfully forked the QMK firmware and prepared a PR. A quick acceptance of my submission to Via followed the QMK PR merger.

With a mix of resilience, creativity, and technical flair, the Flowerpad was thus conceived. This journey highlights how a personal endeavor can seamlessly meld functionality and aesthetics, effectively transforming the landscape of the mechanical keyboard world and setting new expectations for what a personal, functional gift can truly be.